Forskellen mellem smedede stålventiler og støbte stålventiler

Smedet stålventilOg støbt stålventil er primært stålsmedningsteknologi, forarbejdningsformen er forskellig.Støbt stålventilSmedning er en flydende støbning, og smedning er en plastisk deformationsproces. Smedning af støbeemner kan forbedre den indre struktur, forbedre organiseringen af gode mekaniske egenskaber, opnå ensartede kornstrukturer. Det er vigtigt at smede emnet for at arbejde hårdt. Støbning vil forårsage organisatorisk afbøjning og organisatoriske defekter. Støbning har naturligvis også sine egne karakteristika. Nogle komplekse støbeemner er ikke lette at åbne, da det kræver støbning.

Hvad er støbt stålmateriale

Støbt stålmateriale er en slags støbelegering med jern som hovedkomponent. Dets kerneegenskaber omfatter høj styrke, god sejhed og fremragende svejseegenskaber. Det bruges hovedsageligt til at fremstille dele med kompleks form, der er vanskelige at smede eller skære og forme, men som kræver høj styrke og plasticitet.

NoteStøbt stålmateriale kan opdeles i støbt kulstofstål og støbt legeret stål i henhold til dets kemiske sammensætning.

Hvad er smedet stålmateriale

Smedet stål er stål, der er forarbejdet ved smedning. Smedning er en fremstillingsproces, der ændrer materialets form uden at smelte det. Smedet stål har en ensartet metalstruktur og fremragende mekaniske egenskaber, herunder høj styrke, god sejhed og fremragende slagfasthed.

Hurtige faktaSmedet stålventil har højere kvalitet end støbt stålventil, kan modstå stor slagkraft, plasticitet, sejhed og andre mekaniske egenskaber er også højere end støbt stål.

Nogle typer smedede stålventiler og støbte stålventiler

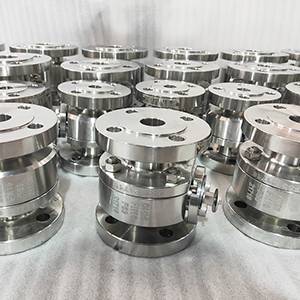

Dernæst vil NEWSWAY Valve Company introducere dig til to almindelige, vores virksomhed producerede smedede stålkugleventilprodukter:

Smedet stålkugleventil refererer til brugen af smedemetoden og produktionen af alle slags smedematerialer og smedegods.

1. Fast smedet stålkugleventil

Den bruges primært til at afskære eller forbinde mediet i rørledningen, og kan også bruges til væskeregulering og -styring. Multipass-kugleventilen i rørledningen kan ikke kun fleksibelt styre mediets sammenløb, omledning og strømningsretningskontakt, men kan også lukke enhver kanal og forbinde de to andre kanaler.

2. Flydende smedet stålkugleventil

Alle dele af produktet er smedegods, der bruger en nedre monteringsventilstamme, udstyrets inverterede tætningsstruktur, indlagt ventilsæde, ventilsæde bag udstyrets O-ring for at sikre, at mediet ikke lækker.

På samme måde vil vi, med vores to produkter som eksempler, kort introducere de almindelige ventilprodukter i støbt stål:

1. Fast kugleventil i støbt stål

By kugleventil i støbt stålÅbnings- og lukkedelene (kuglen) drives af ventilstammen og drejes omkring ventilstammens akse for at muliggøre ventilens roterende bevægelse. Bruges primært til at afskære eller forbinde mediet i rørledningen, kan også bruges til væskeregulering og -styring, især egnet til fibre, små faste materialer og andre medier.

2. API 600skydeventil i støbt stål

Den er egnet til at skære eller forbinde rørledningsmedier i olieindustrien, den kemiske industri, termiske kraftværker og andre arbejdsforhold i ANSI klasse 150 ~ 2500 med en driftstemperatur < 600 ℃. Anvendeligt medium: vand, olie, damp osv. Driftstilstand: manuel, geardrevet, elektrisk, pneumatisk osv.

Opslagstidspunkt: 1. december 2021